SW Series

NC车床旋转型顶尖

SW-Series

- 采用特殊油封,有效防止切削液和异物质进入

- 采用高精度三重轴承结构,回转精度高,寿命长

- 跳动公差为0.003mm以内

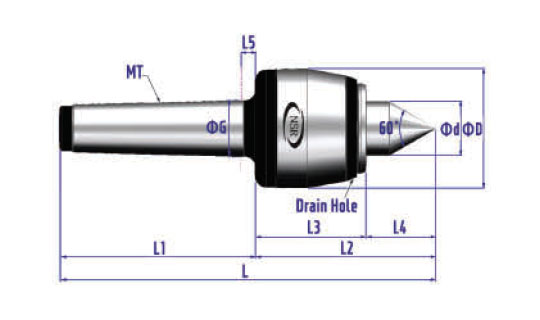

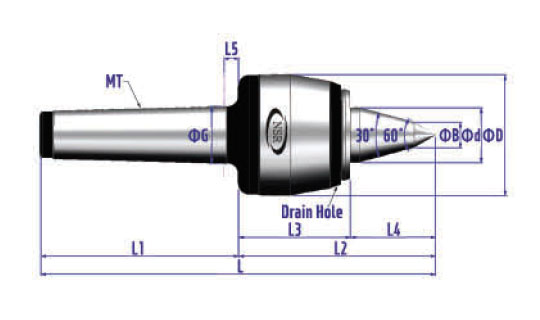

NSR-SW TYPE

- 顶尖头的热处理硬度为HRC 58-62

向左/向右滚动

| Model NO |

Model | Morse Taper | Dimension | MAX Weight(kg) |

MAX R.P.M |

MAX Run Out(㎜) |

|||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΦD | Φd | L | L1 | L2 | L3 | L4 | L5 | ||||||

| 1011003 | 3SW | MT3 | 49 | 24 | 165.5 | 85 | 80.5 | 51.5 | 29 | 6 | 500 | 5,000 | 0.003 |

| 1011004 | 4SW | MT4 | 66 | 30 | 207.5 | 108 | 99.5 | 61 | 38.5 | 8 | 800 | 3,800 | 0.003 |

| 1011005 | 5SW | MT5 | 83 | 39 | 259 | 136 | 123 | 73 | 50 | 8 | 2,000 | 3,000 | 0.003 |

| 1011006 | 6SW | MT6 | 105 | 49 | 330 | 189 | 141 | 81 | 60 | 10 | 3,500 | 2,800 | 0.003 |

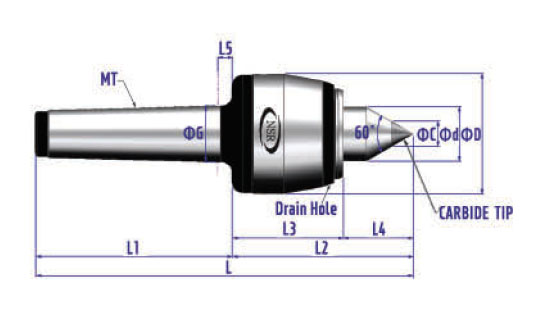

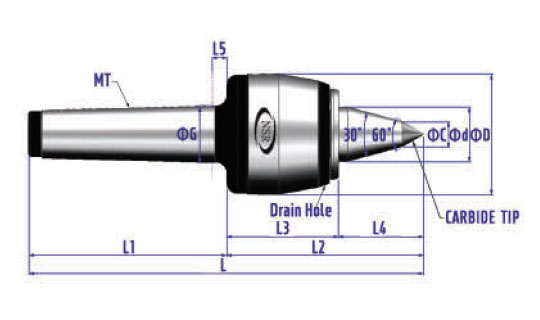

NSR-SWC TYPE

- 顶尖头部镶入硬质合金,耐磨性显著提高

- 硬质合金硬度为HRA 90-91

向左/向右滚动

| Model NO |

Model | Morse Taper | Dimension | MAX Weight(kg) |

MAX R.P.M |

MAX Run Out(㎜) |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΦD | Φd1 | L | L1 | L2 | L3 | L4 | L5 | ΦC | ||||||

| 1011013 | 3SWC | MT3 | 49 | 24 | 165.5 | 85 | 80.5 | 51.5 | 29 | 6 | 10 | 500 | 5,000 | 0.003 |

| 1011014 | 4SWC | MT4 | 66 | 30 | 207.5 | 108 | 99.5 | 61 | 38.5 | 8 | 14 | 800 | 3,800 | 0.003 |

| 1011015 | 5SWC | MT5 | 83 | 39 | 259 | 136 | 123 | 73 | 50 | 8 | 18 | 2,000 | 3,000 | 0.003 |

| 1011016 | 6SWC | MT6 | 105 | 49 | 330 | 189 | 141 | 81 | 60 | 10 | 30 | 3,500 | 2,800 | 0.003 |

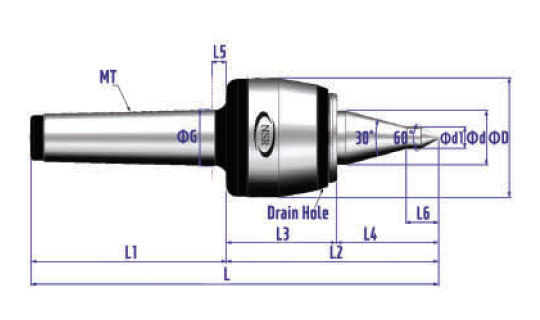

NSR-SWA TYPE

- 顶尖头部采用两段锥度设计,有效减少干涉

- 顶尖头的热处理硬度为HRC58-62

向左/向右滚动

| Model NO |

Model | Morse Taper | Dimension | MAX Weight(kg) |

MAX R.P.M |

MAX Run Out(㎜) |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΦD | Φd | L | L1 | L2 | L3 | L4 | L5 | ΦB | ||||||

| 1011023 | 3SWA | MT3 | 49 | 24 | 176.5 | 85 | 91.5 | 51.5 | 40 | 6 | 10 | 300 | 5,000 | 0.003 |

| 1011024 | 4SWA | MT4 | 66 | 30 | 215.5 | 108 | 107.5 | 61 | 46.5 | 8 | 14 | 500 | 3,800 | 0.003 |

| 1011025 | 5SWA | MT5 | 83 | 39 | 267.3 | 136 | 131.3 | 73 | 58.3 | 8 | 18 | 1,500 | 3,000 | 0.003 |

| 1011026 | 6SWA | MT6 | 105 | 49 | 348 | 189 | 159 | 81 | 78 | 10 | 18 | 2,500 | 2,800 | 0.003 |

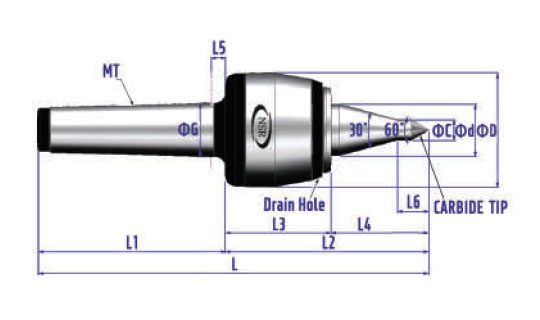

NSR-SWAC TYPE

- 顶尖头部采用两段锥度设计,有效减少干涉

- 顶尖头部镶入硬质合金,耐磨性显著提高

- 硬质合金硬度为HRA 90-91

向左/向右滚动

| Model NO |

Model | Morse Taper | Dimension | MAX Weight(kg) |

MAX R.P.M |

MAX Run Out(㎜) |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΦD | Φd | L | L1 | L2 | L3 | L4 | L5 | ΦC | ||||||

| 1011033 | 3SWAC | MT3 | 49 | 24 | 176.5 | 85 | 91.5 | 51.5 | 40 | 6 | 10 | 300 | 5,000 | 0.003 |

| 1011034 | 4SWAC | MT4 | 66 | 30 | 215.5 | 108 | 107.5 | 61 | 46.5 | 8 | 14 | 500 | 3,800 | 0.003 |

| 1011035 | 5SWAC | MT5 | 83 | 39 | 267.3 | 136 | 131.3 | 73 | 58.3 | 8 | 18 | 1,500 | 3,000 | 0.003 |

| 1011036 | 6SWAC | MT6 | 105 | 49 | 348 | 189 | 159 | 81 | 78 | 10 | 18 | 2,500 | 2,800 | 0.003 |

NSR-SWAL TYPE

- 最大限度减少刀具干涉

- 顶尖头的热处理硬度为HRC 58-62

向左/向右滚动

| Model NO |

Model | Morse Taper | Dimension | MAX Weight(kg) |

MAX R.P.M |

MAX Run Out(㎜) |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΦD | Φd | L | L1 | L2 | L3 | L4 | L5 | L6 | Φd1 | ||||||

| 1001103 | 3SNNAL | MT3 | 49 | 24 | 184.6 | 85 | 99.6 | 51.5 | 48.1 | 6 | 19 | 10 | 300 | 5,000 | 0.003 |

| 1001104 | 4SNNAL | MT4 | 66 | 30 | 225.5 | 108 | 117.5 | 61 | 56.5 | 8 | 18 | 12 | 500 | 3,800 | 0.003 |

| 1001105 | 5SNNAL | MT5 | 83 | 39 | 279.2 | 136 | 143.2 | 73 | 70.2 | 8 | 19.5 | 14 | 1,500 | 3,000 | 0.003 |

| 1001106 | 6SNNAL | MT6 | 105 | 49 | 370 | 189 | 181 | 81 | 100 | 10 | 30 | 14 | 2,500 | 2,800 | 0.003 |

NSR-SWALC TYPE

- 最大限度减少刀具干涉

- 顶尖头部镶入硬质合金,耐磨性显著提高

- 硬质合金硬度为HRA 90-91

向左/向右滚动

| Model NO |

Model | Morse Taper | Dimension | MAX Weight(kg) |

MAX R.P.M |

MAX Run Out(㎜) |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΦD | Φd | L | L1 | L2 | L3 | L4 | L5 | L6 | Φd1 | ||||||

| 1011053 | 3SWALC | MT3 | 49 | 24 | 184.6 | 85 | 99.6 | 51.5 | 48.1 | 6 | 19 | 10 | 300 | 5,000 | 0.003 |

| 1011054 | 4SWALC | MT4 | 66 | 30 | 225.5 | 108 | 117.5 | 61 | 56.5 | 8 | 18 | 12 | 500 | 3,800 | 0.003 |

| 1011055 | 5SWALC | MT5 | 83 | 39 | 279.2 | 136 | 143.2 | 73 | 70.2 | 8 | 19.5 | 14 | 1,500 | 3,000 | 0.003 |

| 1011056 | 6SWALC | MT6 | 105 | 49 | 370 | 189 | 181 | 81 | 100 | 10 | 30 | 14 | 2,500 | 2,800 | 0.003 |