SSH Series

For High-speed Rotation

SSH-Series

- High-speed precision bearing structure.

- Using the non-sontact oil seal to prevent heat-resistant, coolant and foreign matter ingress.

- It facilitates high speed precision work.

- Run out - Max 0.002mm

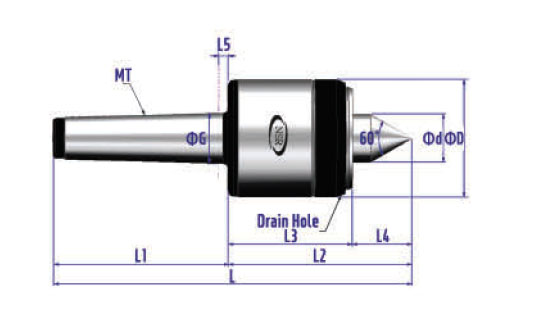

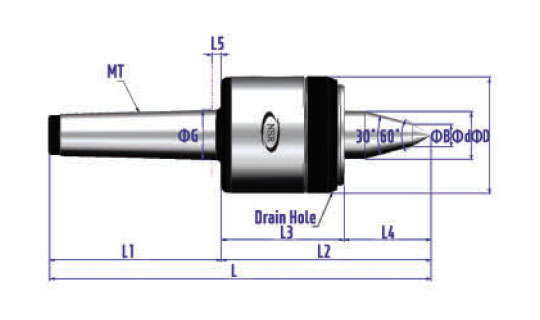

NSR-SSH TYPE

- Heat treatment hardness of center axis, HRC 58~62

Scroll Left / Right

| Model NO |

Model | Morse Taper | Dimension | MAX Weight(kg) |

MAX R.P.M |

MAX Run Out(㎜) |

|||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΦD | Φd | L | L1 | L2 | L3 | L4 | L5 | ||||||

| 1012002 | 2SH | MT2 | 49 | 20 | 149 | 68 | 81 | 55.5 | 25.5 | 4.5 | 350 | 15,000 | 0.002 |

| 1012003 | 3SH | MT3 | 49 | 20 | 166 | 85 | 81 | 55.5 | 25.5 | 4.5 | 350 | 15,000 | 0.002 |

| 1012004 | 4SH | MT4 | 73 | 30 | 222 | 108 | 114 | 77 | 37 | 6 | 650 | 12,000 | 0.002 |

| 1012005 | 5SH | MT5 | 73 | 30 | 250 | 136 | 114 | 77 | 37 | 6 | 650 | 12,000 | 0.002 |

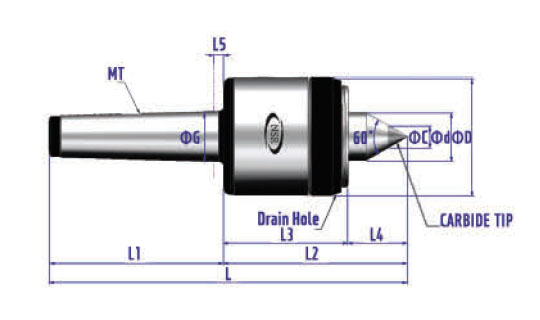

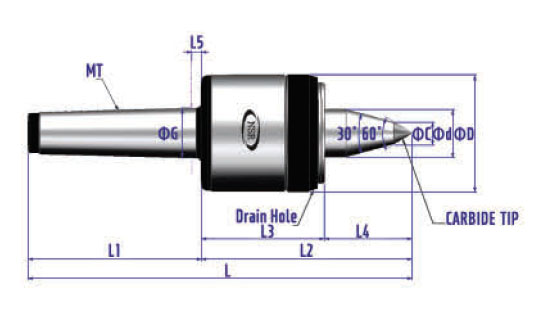

NSR-SSHC TYPE

- Minimized the wear property by inserting tungsten admium alloy (=tungalloy) to center position.

- Hardness of the tungsten cadmuim alloy (=tungalloy) HRA 90~91

Scroll Left / Right

| Model NO |

Model | Morse Taper | Dimension | MAX Weight(kg) |

MAX R.P.M |

MAX Run Out(㎜) |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΦD | Φd | L | L1 | L2 | L3 | L4 | L5 | ΦC | ||||||

| 1023012 | 2SHC | MT2 | 49 | 20 | 149 | 68 | 81 | 55.5 | 25.5 | 4.5 | 10 | 350 | 15,000 | 0.002 |

| 1023013 | 3SHC | MT3 | 49 | 20 | 166 | 85 | 81 | 55.5 | 25.5 | 4.5 | 10 | 350 | 15.000 | 0.002 |

| 1023014 | 4SHC | MT4 | 73 | 30 | 222 | 108 | 114 | 77 | 37 | 6 | 14 | 650 | 12,000 | 0.002 |

| 1023015 | 5SHC | MT5 | 73 | 30 | 250 | 136 | 114 | 77 | 37 | 6 | 18 | 650 | 12,000 | 0.002 |

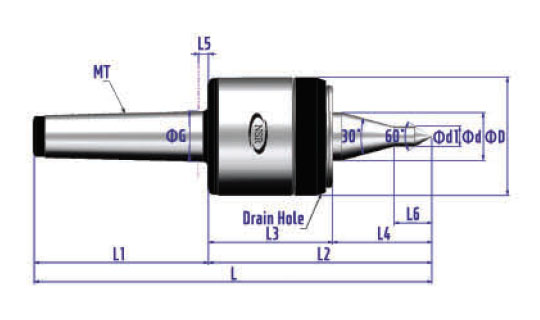

NSR-SSHA TYPE

- Second step-angle application for minimize the bite-interference

- Heat treatment hardness of center axis, HRC 58~62

Scroll Left / Right

| Model NO |

Model | Morse Taper | Dimension | MAX Weight(kg) |

MAX R.P.M |

MAX Run Out(㎜) |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΦD | Φd | L | L1 | L2 | L3 | L4 | L5 | ΦB | ||||||

| 1012022 | 2SHA | MT2 | 49 | 20 | 155.5 | 68 | 87.5 | 55.5 | 32 | 4.5 | 10 | 280 | 15,000 | 0.002 |

| 1012023 | 3SHA | MT3 | 49 | 20 | 172.5 | 85 | 87.5 | 55.5 | 32 | 4.5 | 10 | 280 | 15,000 | 0.002 |

| 1012024 | 4SHA | MT4 | 73 | 30 | 236 | 108 | 128 | 77 | 51 | 6 | 14 | 450 | 12,000 | 0.002 |

| 1012025 | 5SHA | MT5 | 73 |

30 | 264 | 136 | 128 | 77 | 51 | 6 | 16 | 450 | 12,000 | 0.002 |

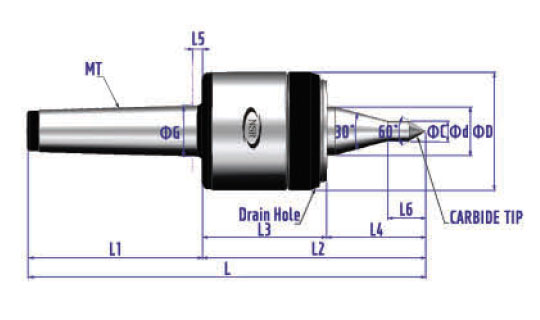

NSR-SSHAC TYPE

- Second step-angle application for minimize the bite-interference

- Minimized the wear property by inserting tungsten admium alloy (=tungalloy) to center position.

- Hardness of the tungsten cadmium alloy (=tungalloy) HRA 90~91

Scroll Left / Right

| Model NO |

Model | Morse Taper | Dimension | MAX Weight(kg) |

MAX R.P.M |

MAX Run Out(㎜) |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΦD | Φd | L | L1 | L2 | L3 | L4 | L5 | ΦC | ||||||

| 1023032 | 2SHAC | MT2 | 49 | 20 | 155.5 | 68 | 87.5 | 55.5 | 32 | 4.5 | 10 | 280 | 15,000 | 0.002 |

| 1023033 | 3SHAC | MT3 | 49 | 20 | 172.5 | 85 | 87.5 | 55.5 | 32 | 4.5 | 10 | 280 | 15,000 | 0.002 |

| 1023034 | 4SHAC | MT4 | 73 | 30 | 236 | 108 | 128 | 77 | 51 | 6 | 14 | 450 | 12,000 | 0.002 |

| 1023035 | 5SHAC | MT5 | 73 | 30 | 264 | 136 | 128 | 77 | 51 | 6 | 16 | 450 | 12,000 | 0.002 |

NSR-SSHAL TYPE

- Minimized the bite-interference

- Heat treatment hardness of center axis, HRC 58~62

Scroll Left / Right

| Model NO |

Model | Morse Taper | Dimension | MAX Weight(kg) |

MAX R.P.M |

MAX Run Out(㎜) |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΦD | Φd | L | L1 | L2 | L3 | L4 | L5 | L6 | Φd1 | ||||||

| 1012042 | 2SHAL | MT2 | 49 | 20 | 166.5 | 68 | 98.5 | 55.5 | 43 | 4.5 | 19 | 10 | 250 | 15,000 | 0.002 |

| 1012043 | 3SHAL | MT3 | 49 | 20 | 183.5 | 85 | 98.5 | 55.5 | 43 | 4.5 | 19 | 10 | 250 | 15,000 | 0.002 |

| 1012044 | 4SHAL | MT4 | 73 | 30 | 246.5 | 108 | 138.5 | 77 | 61.5 | 6 | 23.5 | 12.5 | 390 | 12,000 | 0.002 |

| 1012045 | 5SHAL | MT5 | 73 | 30 | 274.5 | 136 | 138.5 | 77 | 61.5 | 6 | 23.5 | 12.5 | 390 | 12,000 | 0.002 |

NSR-SSHALC TYPE

- Minimized the bite-interference

- Minimized the wear property by inserting tungsten admium alloy (=tungalloy) to center position.

- Hardness of the tungsten cadmium alloy (=tungalloy) HRA 90~91

Scroll Left / Right

| Model NO |

Model | Morse Taper | Dimension | MAX Weight(kg) |

MAX R.P.M |

MAX Run Out(㎜) |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΦD | Φd | L | L1 | L2 | L3 | L4 | L5 | L6 | ΦC | ||||||

| 1012052 | 2SSHALC | MT2 | 49 | 20 | 166.5 | 68 | 98.5 | 55.5 | 43 | 4.5 | 19 | 10 | 250 | 15,000 | 0.002 |

| 1012053 | 3SSHALC | MT3 | 49 | 20 | 183.5 | 85 | 98.5 | 55.5 | 43 | 4.5 | 19 | 10 | 250 | 15,000 | 0.002 |

| 1012054 | 4SSHALC | MT4 | 73 | 30 | 246.5 | 108 | 138.5 | 77 | 61.5 | 6 | 23.5 | 12.5 | 390 | 12,000 | 0.002 |

| 1012055 | 5SSHALC | MT5 | 73 | 30 | 274.5 | 136 | 138.5 | 77 | 61.5 | 6 | 23.5 | 12.5 | 390 | 12,000 | 0.002 |