SNN Series

The Rotation Center for NC Machining

SNN-Series

- Prevention the penetration of cutting oil and extraneous bodies by using the special oil seal

- High degree of accuracy of rotation and high durability by using the triplexed bearing structures as high degree of precision

- Run out-Max 0.003㎜

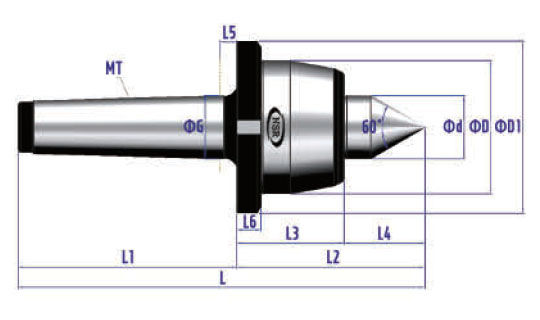

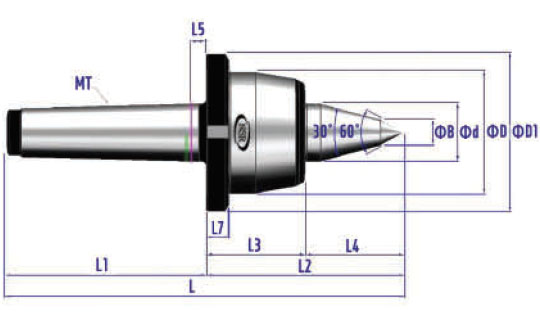

NSR-SNN TYPE

- Detachable by NUT attaching

- Heat treatment hardness of center axis, HRC 58~62

Scroll Left / Right

| Model NO |

Model | Morse Taper | Dimension | MAX Weight(kg) |

MAX R.P.M |

MAX Run Out(㎜) |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΦD | ΦD1 | Φd | L | L1 | L2 | L3 | L4 | L5 | L6 | ||||||

| 1001062 | 2SNN | MT2 | 49 | 65 | 25 | 140 | 68 | 72 | 42 | 30 | 6 | 10 | 500 | 5,000 | 0.003 |

| 1001063 | 3SNN | MT3 | 49 | 65 | 25 | 157 | 85 | 72 | 42 | 30 | 6 | 10 | 500 | 5,000 | 0.003 |

| 1001064 | 4SNN | MT4 | 66 | 85 | 31.4 | 201 | 108 | 93 | 53 | 40 | 8 | 12 | 800 | 3,800 | 0.003 |

| 1001065 | 5SNN | MT5 | 83 | 105 | 40 | 251 | 136 | 115 | 65 | 50 | 8 | 15 | 2,000 | 3,000 | 0.003 |

| 1001066 | 6SNN | MT6 | 105 | 125 | 50 | 324 | 189 | 135 | 75 | 60 | 10 | 17 | 3,500 | 2,800 | 0.003 |

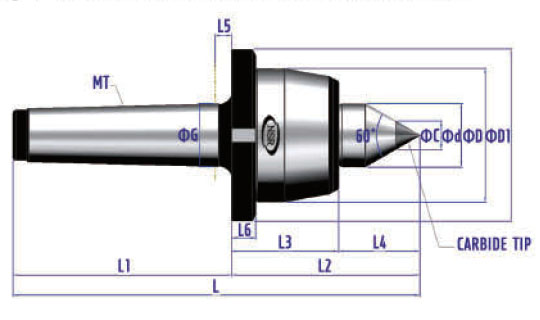

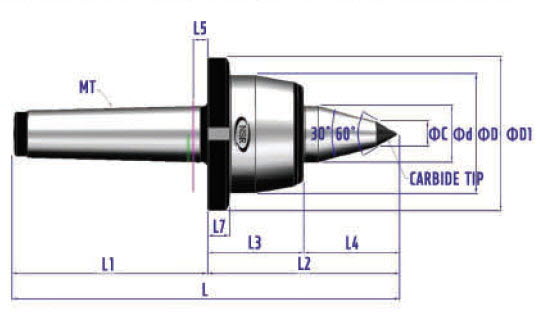

NSR-SNNC TYPE

- Detachable by NUT attaching

- Minimized the wear property by inserting tungsten admium alloy (=tungalloy) to center position.

- Hardness of the tungsten cadmium alloy (=tungalloy) HRA 90~91

Scroll Left / Right

| Model NO |

Model | Morse Taper | Dimension | MAX Weight(kg) |

MAX R.P.M |

MAX Run Out(㎜) |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΦD | ΦD1 | Φd | L | L1 | L2 | L3 | L4 | L5 | L6 | ΦC | ||||||

| 1001072 | 2SNNC | MT2 | 49 | 65 | 25 | 140 | 68 | 72 | 42 | 30 | 6 | 10 | 10 | 500 | 5,000 | 0.003 |

| 1001073 | 3SNNC | MT3 | 49 | 65 | 25 | 157 | 85 | 72 | 42 | 30 | 6 | 10 | 10 | 500 | 5,000 | 0.003 |

| 1001074 | 4SNNC | MT4 | 66 | 85 | 31.4 | 201 | 108 | 93 | 53 | 40 | 8 | 12 | 14 | 800 | 3,800 | 0.003 |

| 1001075 | 5SNNC | MT5 | 83 | 105 | 40 | 251 | 136 | 115 | 65 | 50 | 8 | 15 | 18 | 2,000 | 3,000 | 0.003 |

| 1001076 | 6SNNC | MT6 | 105 | 125 | 50 | 324 | 189 | 135 | 75 | 60 | 10 | 17 | 30 | 3,500 | 2,800 | 0.003 |

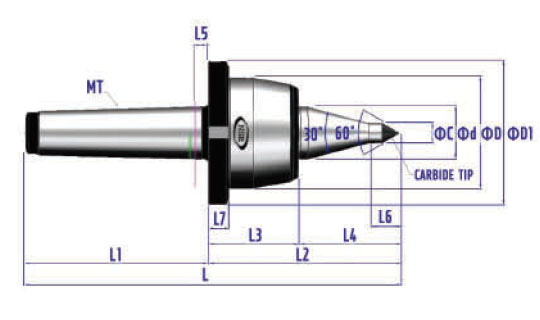

NSR-SNNA TYPE

- Detachable by NUT attaching

- Second step-angle application for minimize the bite-interference

- Heat treatment hardness of center axis, HRC 58~62

Scroll Left / Right

| Model NO |

Model | Morse Taper | Dimension | MAX Weight(kg) |

MAX R.P.M |

MAX Run Out(㎜) |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΦD | ΦD1 | Φd | L | L1 | L2 | L3 | L4 | L5 | L7 | ΦB | ||||||

| 1001082 | 2SNNA | MT2 | 49 | 65 | 25 | 155 | 68 | 87 | 42 | 45 | 6 | 10 | 10 | 300 | 5,000 | 0.003 |

| 1001083 | 3SNNA | MT3 | 49 | 65 | 25 | 172 | 85 | 87 | 42 | 45 | 6 | 10 | 10 | 300 | 5,000 | 0.003 |

| 1001084 | 4SNNA | MT4 | 66 | 85 | 31.4 | 214 | 108 | 106 | 53 | 53 | 8 | 12 | 14 | 500 | 3,800 | 0.003 |

| 1001085 | 5SNNA | MT5 | 83 | 105 | 40 | 266 | 136 | 130 | 65 | 65 | 8 | 15 | 16 | 1,500 | 3,000 | 0.003 |

| 1001086 | 6SNNA | MT6 | 105 | 125 | 50 | 342 | 189 | 153 | 75 | 78 | 10 | 17 | 18 | 2,500 | 2,800 | 0.003 |

NSR-SNNAC TYPE

- Detachable by NUT attaching

- Second step-angle application for minimize the bite-interference

- Minimized the wear property by inserting tungsten admium alloy (=tungalloy) to center position.

- Hardness of the tungsten cadmium alloy (=tungalloy) HRA 90~91

Scroll Left / Right

| Model NO |

Model | Morse Taper | Dimension | MAX Weight(kg) |

MAX R.P.M |

MAX Run Out(㎜) |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΦD | ΦD1 | Φd | L | L1 | L2 | L3 | L4 | L5 | L6 | ΦC | ||||||

| 1001092 | 2SNNAC | MT2 | 49 | 65 | 25 | 155 | 68 | 87 | 42 | 45 | 6 | 10 | 10 | 300 | 5,000 | 0.003 |

| 1001093 | 3SNNAC | MT3 | 49 | 65 | 25 | 172 | 85 | 87 | 42 | 45 | 6 | 10 | 10 | 300 | 5,000 | 0.003 |

| 1001094 | 4SNNAC | MT4 | 66 | 85 | 31.4 | 214 | 108 | 106 | 53 | 53 | 8 | 12 | 14 | 500 | 3,800 | 0.003 |

| 1001095 | 5SNNAC | MT5 | 83 | 105 | 40 | 266 | 136 | 130 | 65 | 65 | 8 | 15 | 16 | 1,500 | 3,000 | 0.003 |

| 1001096 | 6SNNAC | MT6 | 105 | 125 | 50 | 342 | 189 | 153 | 75 | 78 | 10 | 17 | 18 | 2,500 | 2,800 | 0.003 |

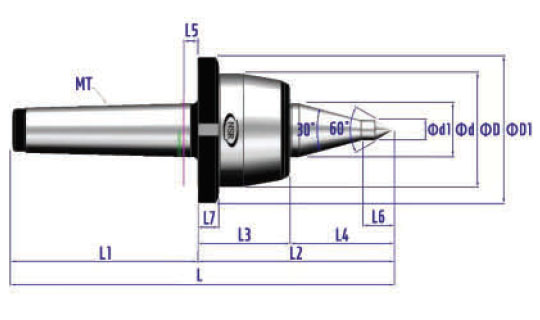

NSR-SNNAL TYPE

- Detachable by NUT attaching

- Minimized the bite-interference

- Heat treatment hardness of center axis, HRC 58~62

Scroll Left / Right

| Model NO |

Model | Morse Taper | Dimension | MAX Weight(kg) |

MAX R.P.M |

MAX Run Out(㎜) |

|||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΦD | ΦD1 | Φd | L | L1 | L2 | L3 | L4 | L5 | L6 | L7 | Φd1 | ||||||

| 1001102 | 2SNNAL | MT2 | 49 | 65 | 25 | 160 | 68 | 92 | 42 | 50 | 6 | 17 | 10 | 10 | 300 | 5,000 | 0.003 |

| 1001103 | 3SNNAL | MT3 | 49 | 65 | 25 | 177 | 85 | 92 | 42 | 50 | 6 | 17 | 10 | 10 | 300 | 5,000 | 0.003 |

| 1001104 | 4SNNAL | MT4 | 66 | 85 | 31.4 | 221 | 108 | 113 | 53 | 60 | 8 | 18 | 12 | 12 | 500 | 3,800 | 0.003 |

| 1001105 | 5SNNAL | MT5 | 83 | 105 | 40 | 276 | 136 | 140 | 65 | 75 | 8 | 17.5 | 15 | 12 | 1,500 | 3,000 | 0.003 |

| 1001106 | 6SNNAL | MT6 | 105 | 125 | 50 | 359 | 189 | 170 | 75 | 95 | 10 | 25 | 17 | 14 | 2,500 | 2,800 | 0.003 |

NSR-SNNALC TYPE

- Detachable by NUT attaching

- Minimized the bite-interference

- Minimized the wear property by inserting tungsten admium alloy (=tungalloy) to center position.

- Hardness of the tungsten cadmium alloy (=tungalloy) HRA 90~91

Scroll Left / Right

| Model NO |

Model | Morse Taper | Dimension | MAX Weight(kg) |

MAX R.P.M |

MAX Run Out(㎜) |

|||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΦD | ΦD1 | Φd | L | L1 | L2 | L3 | L4 | L5 | L6 | L7 | Φd1 | ||||||

| 1001112 | 2SNNALC | MT2 | 49 | 65 | 25 | 160 | 68 | 92 | 42 | 50 | 6 | 17 | 10 | 10 | 300 | 5,000 | 0.003 |

| 1001113 | 3SNNALC | MT3 | 49 | 65 | 25 | 177 | 85 | 92 | 42 | 50 | 6 | 17 | 10 | 10 | 300 | 5,000 | 0.003 |

| 1001114 | 4SNNALC | MT4 | 66 | 85 | 31.4 | 221 | 108 | 113 | 53 | 60 | 8 | 18 | 12 | 12 | 500 | 3,800 | 0.003 |

| 1001115 | 5SNNALC | MT5 | 83 | 105 | 40 | 276 | 136 | 140 | 65 | 75 | 8 | 17.5 | 15 | 12 | 1,500 | 3,000 | 0.003 |

| 1001116 | 6SNNALC | MT6 | 105 | 125 | 50 | 359 | 189 | 170 | 75 | 95 | 10 | 25 | 17 | 14 | 2,500 | 2,800 | 0.003 |